(SBS) Side-By-Side Dryer Non-Chute Load

Jump To:

Choose a Section

Jump To:

(SBS) Side-By-Side Dryer Non-Chute Load

SEE MORE

Special Features

Side-By-Side Gas Dryers

Side-By-Side Gas Dryers

- Available in 300-400 and 500-600 lb. clean dry weight processing capacities (Gas or Steam)

- A true side-by-side configuration design in chute or non-chute load configurations

- No spacing required with each set of dryers

- All dryers are identical, there are no left and right-hand dryers

- Split Panel Arc Flash Compliant

- This minimizes the amount of spare parts needed

- Ideal for laundries with limited space!

- All Braun dryers feature a reversing capability (standard) which prevents long items such as sheets or mats from becoming tangled or roped.

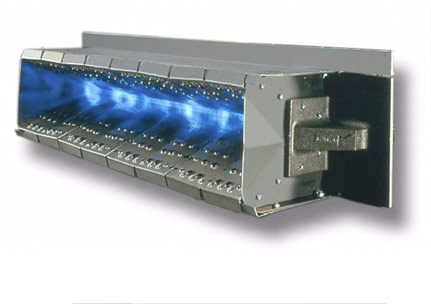

Burner Technology

- Uniform Heat Distribution – – 42″ Direct spark ignition line burner (no pilot) provides uniform heat distribution across the width of the basket. This results in precise basket chamber temperature control, yields fast dry times, consistent quality and outstanding resource efficiency.

- This burner also does not require a maintenance intensive combustion air filter.

Side-By-Side Steam Dryers

- A true side-by-side configuration design.

- No spacing required with each set of dryers

- All dryers are identical, there are no left and right-hand dryers

- This minimizes the amount of spare parts needed

- Ideal for laundries with limited space!

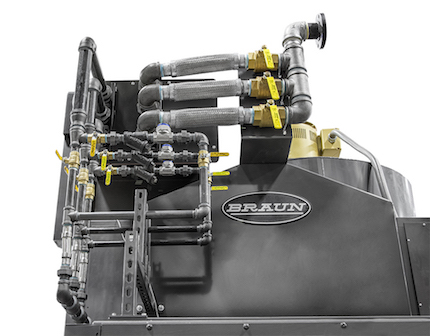

Steam Coils

- High efficiency steam coils provide uniform temperature distribution across the entire width of the basket. This results in precise basket chamber temperature control, yields fast dry times, consistent quality and outstanding resource efficiency.

- Simplified steam duct design with quick disconnects and unions allows for easy troubleshooting and quick component replacement.

- 2 1/2 – 3 Turns per hour at 125 psi steam (based on mix)

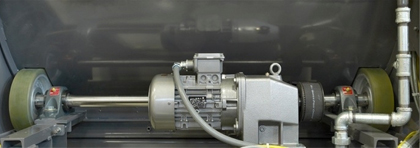

Drive System

- Carbon fiber reinforced belt

- Easy to access and maintain

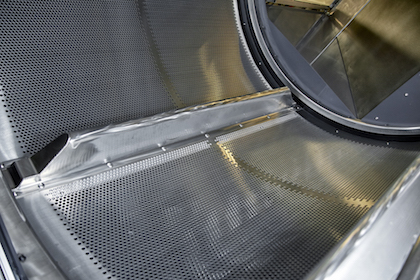

Stainless Steel Removable Basket

- Staggered rib heights to promote exceptional tumbling action

- Positive basket seal system for efficiency and to allow the processing of barrier fabrics

- Optional non-stick coatings available

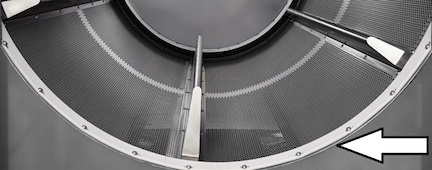

Gap Rings

- Gap rings protect goods such as barrier materials from being pulled and torn

- Gap rings help prolong seal life

Patented Lint Collection

- Light weight

- Individual slide in lint screen

- No clamps or pneumatics to disconnect

- Lint blow down controlled by a linear actuator for precise lint blow down control

Lint Vacuum System

- Braun’s lint vacuum and canister are on casters for easy mobility

- Can be used on all Braun Dryers with internal lint collection systems

- 55 gallon lint canister is made of tough and durable resilient material (unlike others made of fiberglass that can easily shatter and break if dropped)

- The lint vacuum port and blower exhaust were engineered to easily rotate. This offers more flexibility to where the lint vacuum can be positioned wihtin the laundry facility

- This system utilizes sound suppression technology

- The lint sock catches any particulates that may escape through the vacuum filter

- Up to 5 dryers can be serviced with one lint collector

Lint Vacuum – Option

- Braun’s lint vacuum system is also available in blue

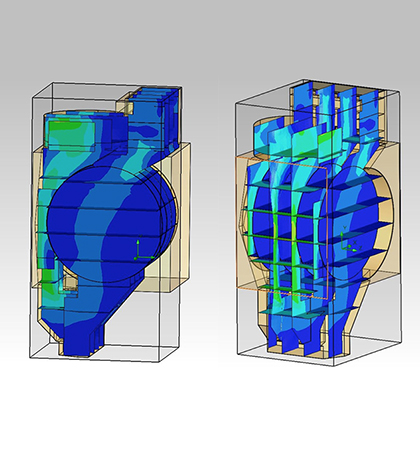

CFD Analysis

- Since the two most important factors in drying goods are airflow and temperature, Braun uses computational fluid dynamics (CFD) to improve airflow and air mixing throughout the dryer.

- The CFD technology helps remove eddy currents, causing the temperature distribution in the basket to improve.

Touch Screen Controls

Simple To Use And Intuitive

- Load

- Unload

- Start

- Cool

- Conveniently located USB flash drive to simplify program loading and backup

- Each machine has a captive and easily accessible 24V PLC. This eliminates the exposures associated with all systems dryers being controlled by one central PLC.

Product Videos

Airflow Operation During Unload Process

Product Literature