PT (Pass-Thru) Dryers Chute Load

Jump To:

Choose a Section

Jump To:

PT (Pass-Thru) Dryers Chute Load

Special Features

General Overview

General Overview

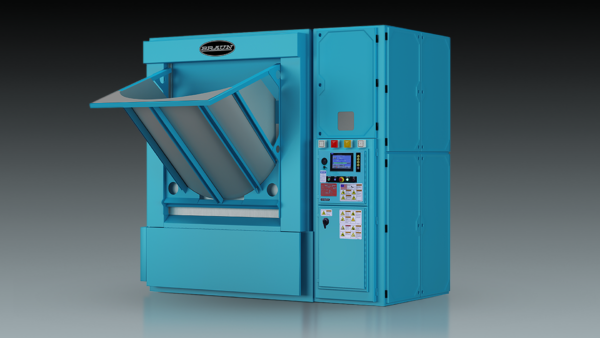

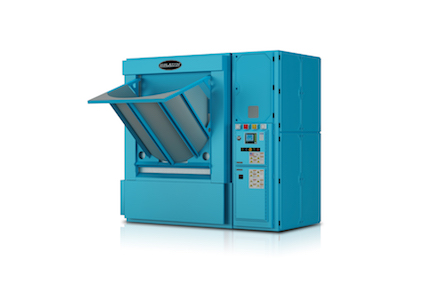

- Available in processing capacities of 300-400, 500-600, and 700-800 lbs. clean dry weight

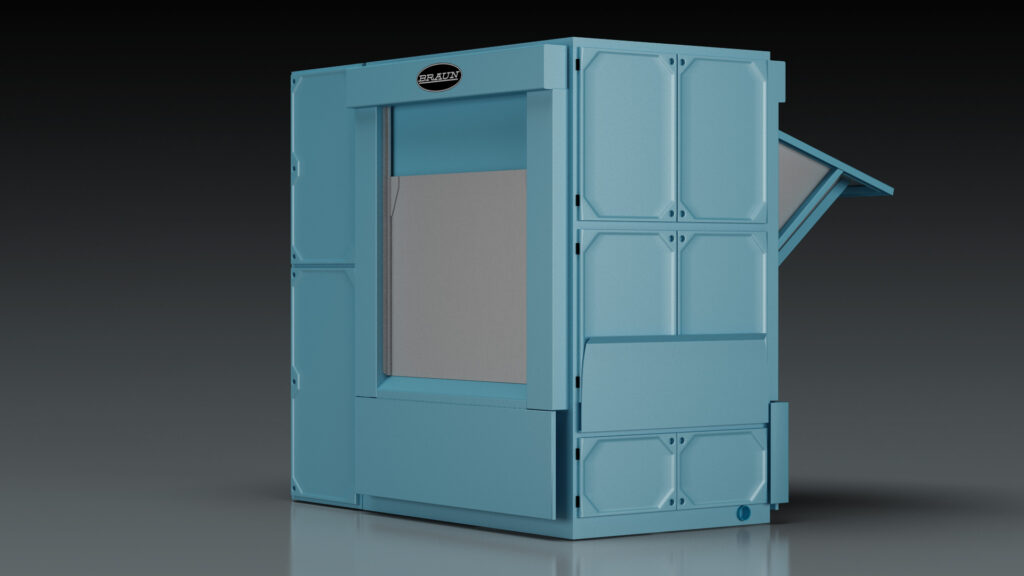

- Chute loading system eliminates shuttle transfer of goods

- In this system, sling bags are released and positioned over the chute on the dryer and dropped into the dryer for processing.

- There is no limitation on goods types in this particular system

- This system provides for great flexibility with respect to washroom configuration

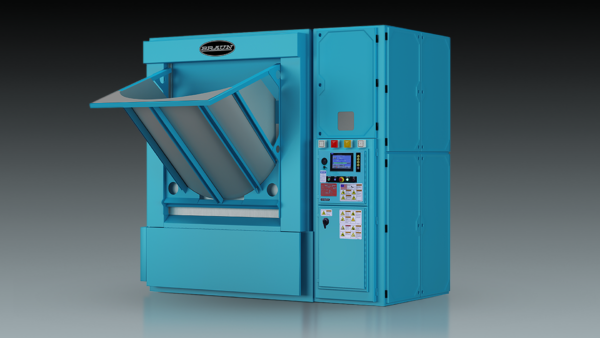

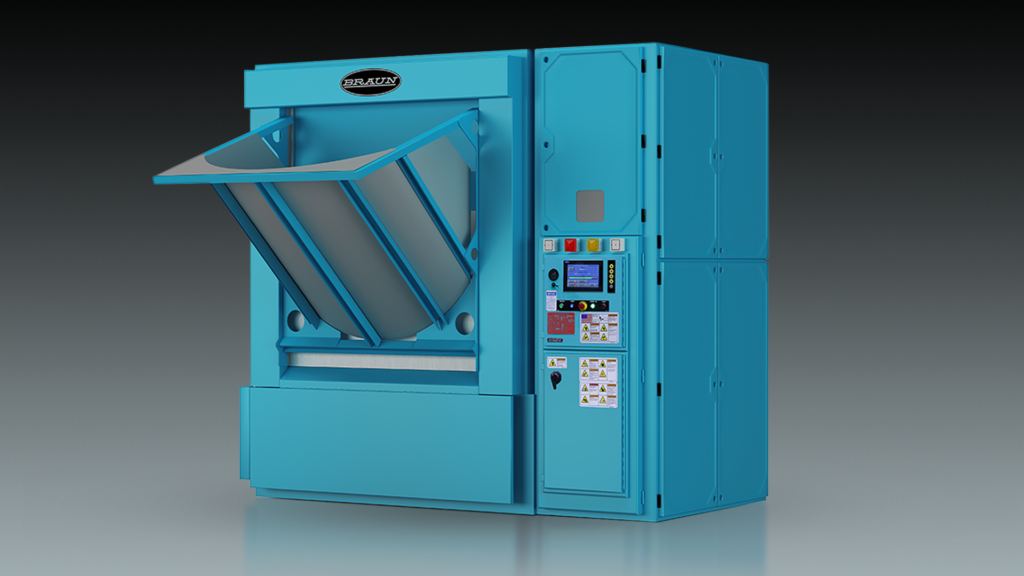

- All Braun dryers have a reversing capability (standard), which can be programmed on Braun’s touch screen controls. The reversing prevents long items such as sheets or mats from becoming tangled or roped.

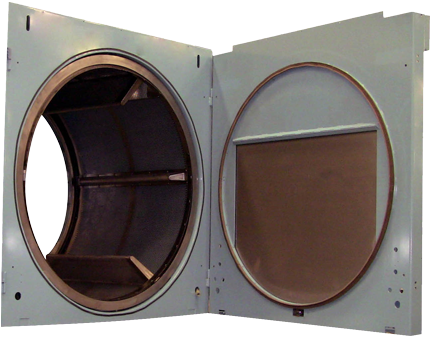

- A front window is standard on all PT Dryers. This allows operators to visually inspect the burner flame without opening the access doors on the dryer.

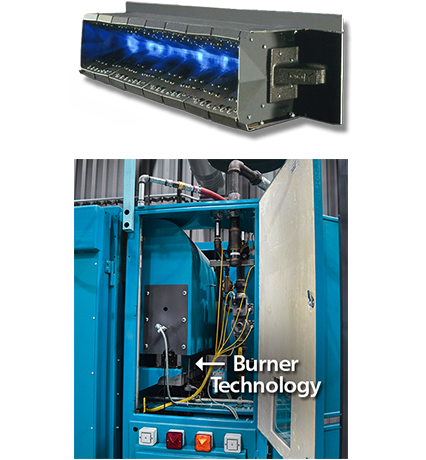

Burner Technology

- Uniform Heat Distribution – – 42″ Direct spark ignition line burner (no pilot) provides uniform heat distribution across the width of the basket. This results in precise basket chamber temperature control, yields fast dry times, consistent quality and outstanding resource efficiency.

- This burner also does not require a maintenance intensive combustion air filter

Steam Chute Load

- PT Chute Load Series Dryers are also available in steam fired models

Low NOx Burner

- True Low NOx qualified dryers – third party tested in California for Low NOx compliance

- A Low Nitrogen Oxide (NOx) burner is available on Braun PT Dryers

- Independent third party testing confirmed Braun is over 90% cleaner than the minimum compliance required by West Coast Air Quality Board Standards1 for NOx emissions.

- * Confirmed testing averaged 2.2 ppm an 0.12 lbs./hr. NOx from the Braun dryer.

Note: The maximum allowable emissions of Nitrogen Oxide is 30 ppm. The third party testing results indicate that Braun dryers are sure to meet any low NOx emission requirement.

*The numbers obtained during third party testing are for dryer process combustion emissions only. Processing goods containing VOC’s will add to the total dryer combustion emissions measured and may cause the measured emissions to exceed the AQB allowable NOx emission standard.

A True Low NOx Qualified Dryer!

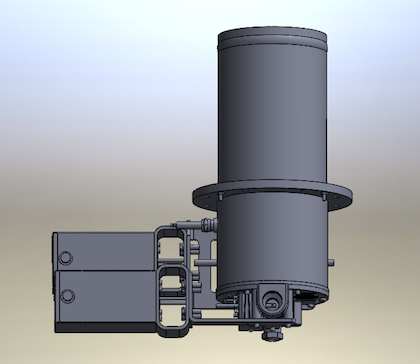

Drive System

- Easy to access and maintain

- Carbon fiber reinforced belt

Insulation

- All dryer doors are fully insulated helping to retain heat within the dryer minimizing temperature loss and providing for a more temperaten workplace

- The doors are also light weight and feature lift off hinges and 90 degree latches. This makes access to the drive and burner components quick and easy.

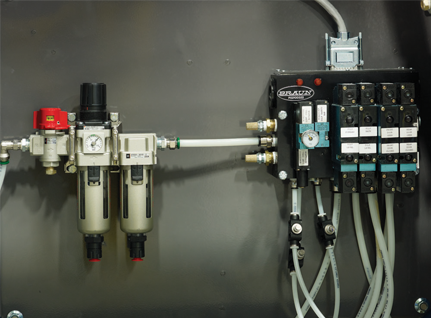

Pneumatics

- The pneumatics on Braun PT series dryers are simplistic, neat, and conveniently located providing easy access for maintenance, and include LED indicators for troubleshooting.

Plug and Play Wire Harness

- If a component should need replacement, simply loosen the harness collar and pull to free the connection. Installation is just as simple.

- Swing-out control box and large doors provide easy access to all harnesses and internal components.

- Other manufacturers use hard wired connections that require time-consuming disconnect and reconnect procedures.

Thrust Wheels

- Thrust wheels on the Braun PT Dryer ensure proper centering of the basket

Gap Rings

- Gap rings protect goods such as barrier materials from being pulled and torn

- Gap rings help prolong seal life

Lint Collection

- Slide rails assist operators to easily remove the lint collection basket for routine maintenance

- System automatically blows down lint from collection basket and removes it to the collection unit outside the dryer at the beginning of each cycle.

- No manual lint collection is required between loads

- The flex hose, air line, and wire for the linear actuator all feature quick disconnect fittings which also assist operators to easily remove the lint collection basket.

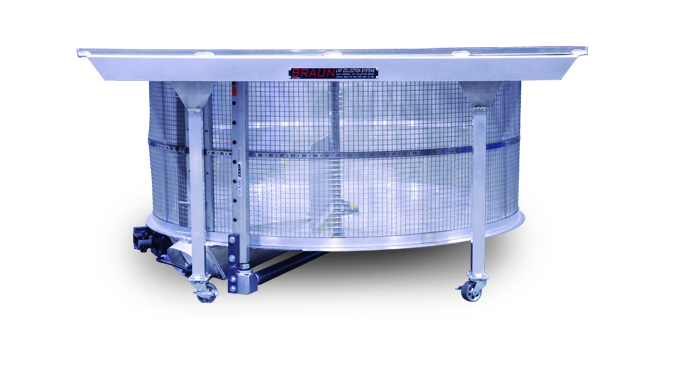

Lint Vacuum System

- Braun’s lint vacuum and canister are on casters for easy mobility

- Can be used on all Braun dryers with internal lint collection systems

- 55 gallon lint canister is made of tough and durable resilient material (unlike others made of fiberglass that can easily shatter and break if dropped)

- The lint vacuum port and blower exhaust were engineered to be easily rotated. This offers more flexibility to where the lint vacuum can be positioned within the laundry facility.

- This system utilizes sound suppression technology

- The lint sock catches any particulates that may escape through the vacuum filter

- Only periodic inspection and maintenance is required.

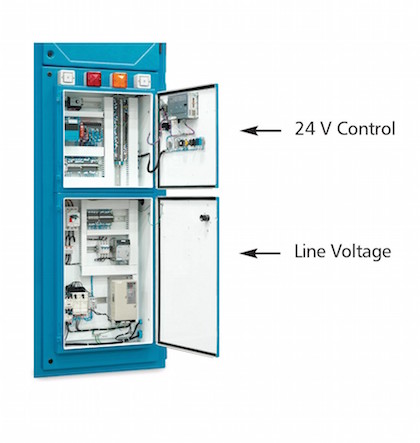

Dual Panel Control Box

- The dual panel control box on Braun PT Series dryers is an exceptional safety feature which separates the high voltage from low voltage components.

Swing-out Faceplates

- Swing-out faceplates were designed for easy access to components to simplify maintenance.

- These faceplates insure an air tight drying vessel for optimal energy efficiency and productivity.

- Insulated – – Fire Retardant

- Stainless and Structural Steel

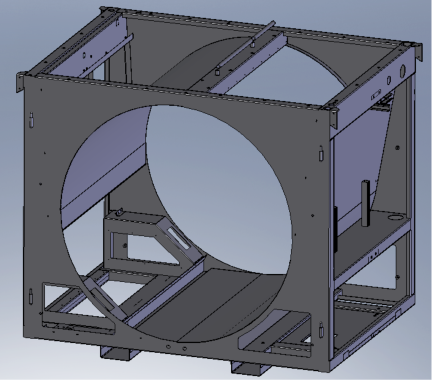

Manufacturing Repeatability

- Airtight Seals – – 3D Modeling helps to eliminate gaps that might be overlooked using 2D drawings, which improves the dryers sealing ability, providing for an airtight vessel.

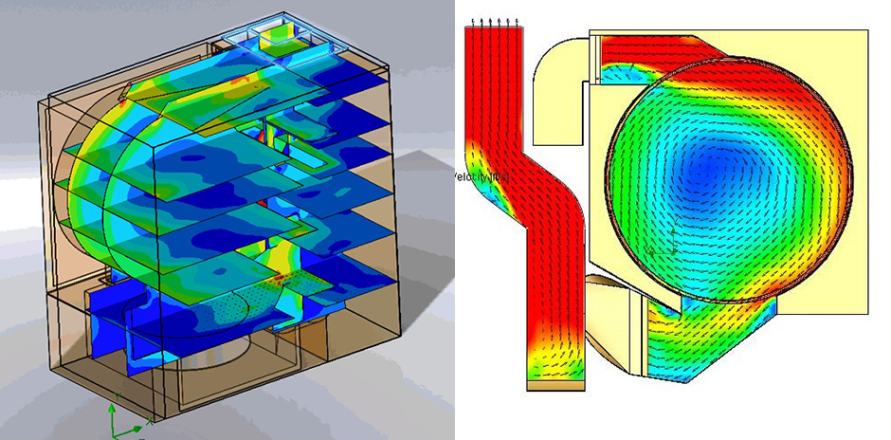

Computational Fluid Dynamics

- Since the two most important factors in drying goods are airflow and temperature, Braun uses computational fluid dynamics (CFD) to improve airflow and air mixing throughout the dryer.

- The CFD technology helps remove eddy currents, causing the temperature distribution in the basket to improve.

Product Videos

Demonstration

Product Literature